Description

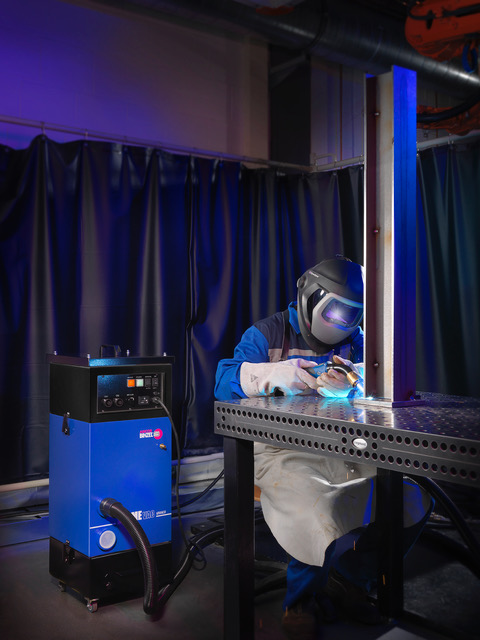

Welding fumes are harmful to health. In addition to dangerous gases, it contains tiny particles that enter the blood via the lungs and can cause diseases. For this reason, employers are obliged to protect welders from these substances in order to prevent serious illnesses such as lung cancer. With xFUME fume extraction systems, ABICOR BINZEL offers powerful solutions to effectively extract fumes and reliably prevent inhalation of harmful particles.

xFUME units work with low or high vacuum technology. Depending on the model, fumes and other small particles released during welding are extracted directly at the point of origin with up to 26,000 PA and cleaned in a special filter. The compact and robust xFUME systems are absolutely suitable for industrial use. Thanks to their castors, they can be conveniently transported wherever fume extraction is required. They work much more efficiently than

stationary or central extraction systems.

Main features

Particularly powerful thanks to high-vacuum technology with more than 20,000 PA negative pressure

Two connections for extraction hoses.

Automatic filter cleaning by compressed air impulse.

Highly efficient thanks to the cartridge filter, which filters out up to 99.9% of all dust > 0.1 µm

Automatic start/stop via current clamp for reduced operating costs and less wear and tear

Compact and robust design with castors for mobile use and easy transport

Technical Data

Max. airflow: 340 m3/h

Connection diameter: 60 mm

Max. vacuum: 20,000 PA

Noise level: ≤ 68 dB (A)

Voltage: 115 V 50/60 Hz / 230 V 50/60 Hz

Motor power: 2 x 0.8 kW

Filter efficiency: ≥ 99.9 %

Cleaning: automatic

Automatic start/stop: Yes

Adjustable air flow: Yes