Description

Inverter Multiprocess power

› A range of high performance multiprocess power sources, particularly suitable for high

production applications.

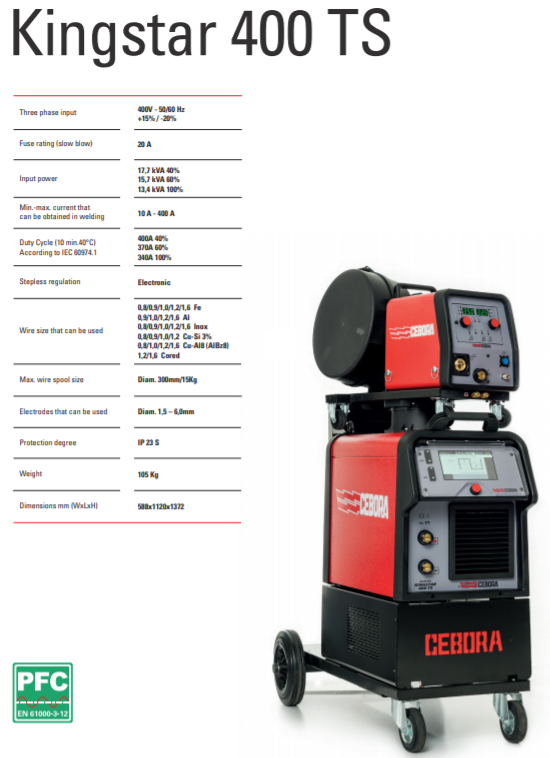

› The 400A power source has been upgraded and has now a duty cycle of 340A @ 100%

and 400A@ 40% (according to IEC 60974.1);

› Devoted package of Welding Procedure Specifications (WPS) according to ISO 151612,

which meets the qualification requirements of the procedures according to EN 1090-1;

› A Spatter Reduction System (SRS) welding process has been added to the HD (High Deposit)

and to the ROOT (first pass) processes in order to achieve completely spatter free welds and

with reduced heat input (on mild steel and stainless steel up to 3mm thickness);

› System calibration procedure, which allows, complete adjustment of all welding parameters

and process variables, from the features of the welding torch, to the connecting cable used

between the trolley and the power source;

› Easily removable power source cooling grille, to facilitate and reduce the maintenance time;

› Power source / wire feed connection with bayonet attachment in accordance with MIL-C-SS

116 standards that eliminates the problem of inserting and fixing the signal cable;

› Integration of the T-LINK system, which brings to zero the delay times for the dimming of the

light reactive welding mask worn by the welder. Thanks to the wireless transmission of data

between power source and mask, it guarantees maximum operator eye protection

and reduces eye fatigue;

› The new hardware architecture of the power source allows the implementation of a web

server, which through LAN connection and Wi-Fi connections, in addition to 2 USB ports,

provides useful functions for remote service, diagnostics, information system, backup and

data recovery etc, also for all those tasks that require data collection and processing;

› The User Interface can be remotely controlled and can be managed through Personal

Computer, Tablet and Smart Phone without the need to install other dedicated software.

Technical Spec